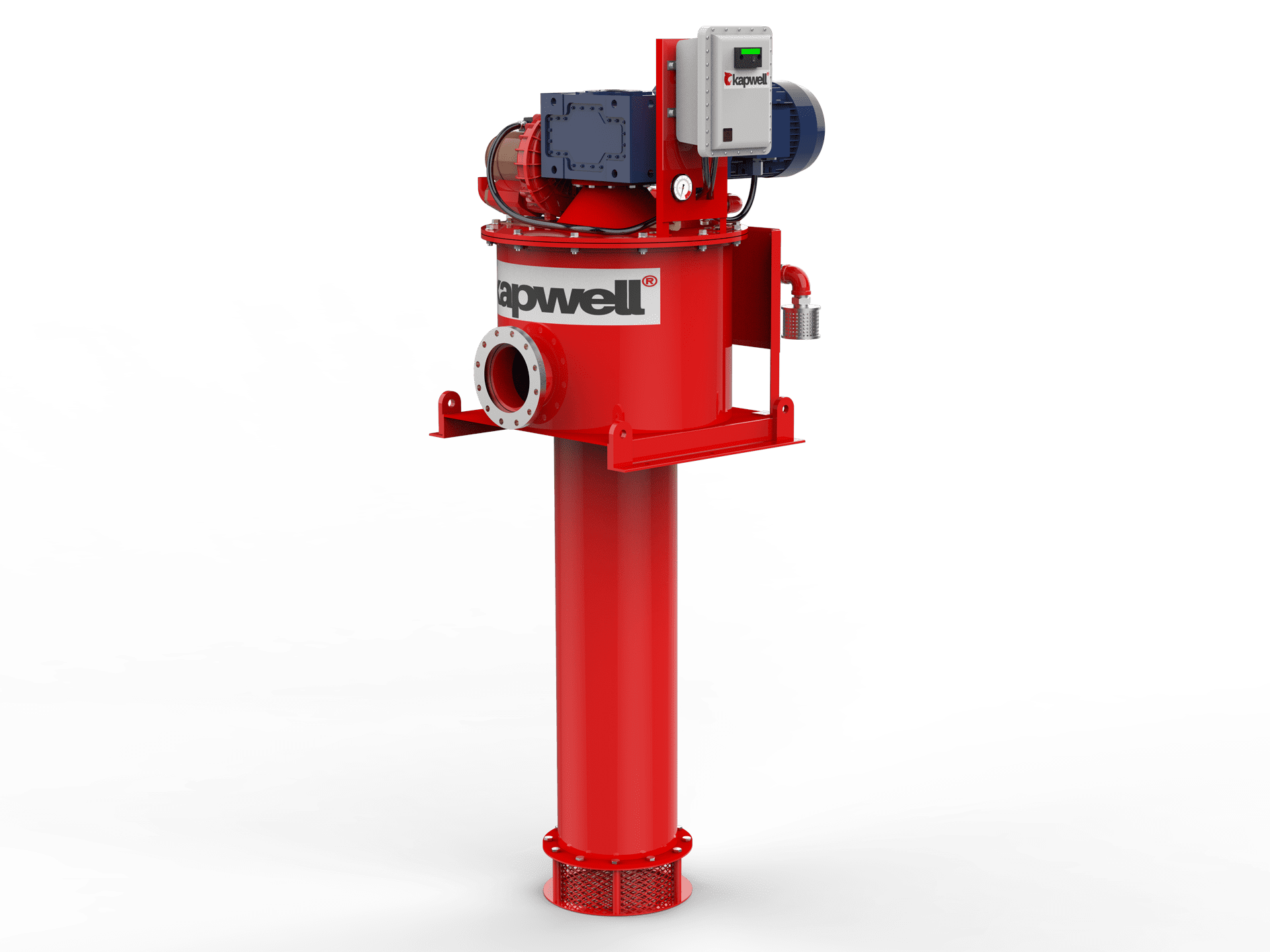

Centrifugal Degasser

- Design Temperature: -20 ºC to 75ºC

- H2S Service NACE MR-01-75

- Max processing Flow up to 2000 GPM

- Gas Processing Rate up to 2,500 ft3/min

- Maximum vacuum of about 20 inches Hg

- Area Classification Zone 1 ATEX CE Marked

- NACE 0175 Certified

- ASME Section VIII Div. 1 Certified Vessel

- Smallest footprint and Compact Design

- Handle high density and high viscosity mud

- Alternative to mud agitator

- Recovers liquid density & eliminate toxic gases

- Efficient degassing and cleaning of drilling mud

- Recover mud gravity & stabilise mud viscosity

- DNV / ABS / BV / Lloyds Certification (Optional)

Certification

Product Overview

The Kapwell centrifugal degasser is the most effective and efficient meets the stringent requirement.

Kapwell supply customised CE/UKCA/NORSOK, ATEX Zone 1 certified centrifugal degasser to suit the client requirements. All our components are NACE certified and manufactured to the highest quality.

Our degassers are designed to achieve an effective gas-liquid separation and ensure a smooth transition of toxic gases to the exhaust pipe.

Kapwell degasser ensures the best mud recovery and stabilises mud viscosity. Our Cenrifugal degassers consist of ASME certified degasser vessel, vacuum pump, motor and control cabinet. The drilling mud from the shaker mud tank gets sucked into the vacuum degasser by a vacuum created by a regenerative vacuum/blower. The vacuum degasser then bursts the mud bubbles, causing a release of harmful gasses such as methane, H₂S, and CO₂ from the mud to the surface. The toxic gases then discharged away from the rig at a safe distance to a flare line or other point of disposal

Contact Kapwell representative for more details.

Features & Benefits

- Capacity up to 2000 GPM

- Maximum vacuum of about 20 inches Hg

- NACE 0175 Certified; reduced cost of maintenance

- Ex equipment design & manufacturing

- ATEX Zone 1 Certified, CE mark

- Visual and/or audible Indicators

- ASEM VIII Certified Degassing Vessel

- Smallest footprint and Compact Design

- Handle high density and high viscosity mud

- Alternative to mud agitator

- Recovers liquid density & eliminate hazardous gases

- Efficient degassing and cleaning of drilling mud

- Emergency Operation Provisions

- Recover mud gravity & stabilise mud viscosity

- Customised vacuum degasser to suit client requirements

Applications

Pulp and Paper

Centrifugal degassers are also used in the pulp and paper industry to remove air bubbles and other gases from pulp slurries. These gases can cause problems such as paper quality defects, poor runnability, and reduced production efficiency. Centrifugal degassers can help improve paper quality, production efficiency, and environmental performance.

Chemical Processing

Centrifugal degassers are used in the chemical processing industry to remove unwanted gases from chemical products such as solvents, polymers, and resins. These gases can affect product performance, safety, and quality. Centrifugal degassers can help improve product purity, consistency, and stability.

Water Treatment

Centrifugal degassers are used in the water treatment industry to remove gases such as hydrogen sulfide and carbon dioxide from water. These gases can cause water quality problems such as odor, taste, and corrosion. Centrifugal degassers can help improve water quality, safety, and environmental protection.

Food and Beverage Industry

Centrifugal degassers are used in the food and beverage industry to remove unwanted gases such as oxygen and carbon dioxide from liquids such as beer, wine, and soft drinks. These gases can affect product flavor, aroma, and stability. Centrifugal degassers can help improve product quality, consistency, and shelf life.

Drilling Fluids

Centrifugal degassers are used in the oil and gas industry to remove gas bubbles and other contaminants from drilling fluids. These gases can cause problems such as poor drilling performance, blowouts, and corrosion. Centrifugal degassers can help improve drilling efficiency, safety, and environmental protection.

NEXT STEPS...

From arctic conditions, desserts, remote locations to harsh offshore facilities and aggressive desert environments, Kapwell provides world-class products and services. For more information contact our sales representative.