Technical Specification

Product Flyer

O&M Manual

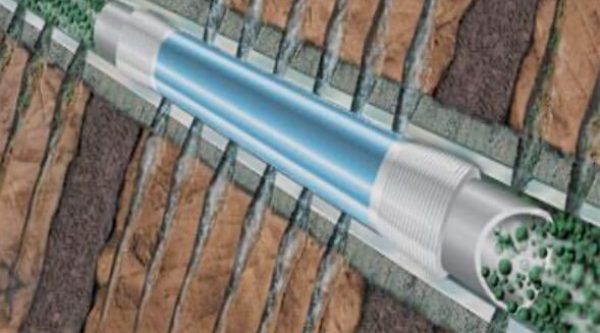

Horizontal Degasser

- Design Temperature: -20 ºC to 105 ºC

- H2S Service NACE MR-01-75

- Max processing Flow up to 2000 GPM

- Gas Processing Rate up to 2,500 ft3/min

- Area Classification Zone 1 ATEX CE Marked

- NACE 0175 Certified

- ASME Section VIII Div. 1 Certified Vessel

- Smallest footprint and Compact Design

- Recovers liquid density & eliminate toxic gases

- Efficient degassing and cleaning of drilling mud

- Recover mud gravity & stabilise mud viscosity

- DNV / ABS / BV / Lloyds Certification (Optional)

Standards

Product Overview

The Kapwell Horizontal Degasser is highly effective and efficient, meeting stringent requirements.

Kapwell supplies customised CE-marked, ATEX Zone 1 certified horizontal degassers tailored to suit client requirements. All our components are NACE certified and manufactured to the highest quality standards.

Our degassers are designed to achieve effective gas-liquid separation and ensure the safe discharge through the vapour outlet. In the feedwater tank, the degassed water is collected. The gases are evacuated along with the generated water vapour using a vacuum pump.

Our horizontal degassers consist of an ASME-certified degasser vessel and a control cabinet.

Contact Kapwell representative for more details.

Safe Design

Design is the safest way to update values. This is due to highest specification.

High Operating Efficiency

The internal design promotes efficient gas separation while ensuring stable pressure conditions during operation.

The Next Generation of Degassers

A highly experienced team of mechanical, process, and thermal design experts collaborated to optimise each and every aspect of Degasser designs for the next generation design.

Applications

Drilling operations

During drilling operations, drilling fluids are used to cool and lubricate the drill bit, as well as to remove rock cuttings from the wellbore. These fluids are typically a mixture of water, oil, and various chemicals, including H2S scavengers. A horizontal degasser is used to remove any H2S that may be present in the fluids before they are re-circulated back into the well.

Oil and Gas Production

Horizontal degassers are also used in oil and gas production operations. When oil or gas is extracted from a well, it contains gas and other contaminants. These contaminants must be removed before the oil or gas can be transported and refined. A horizontal degasser can remove the gas and other contaminants from the extracted oil or gas, making it suitable for transport and refining.

Workover operations

Workover operations involve the maintenance and repair of existing wells. These operations may require the use of fluids that contain H2S, such as acidizing fluids or cementing fluids. A horizontal degasser can be used to remove the H2S from these fluids before they are used in the well.

Completion operations

After a well has been drilled, completion operations are conducted to prepare the well for production. This may involve the use of fluids such as brine, which can contain H2S. A horizontal degasser can be used to remove the H2S before the fluids are injected into the well.

Refining Operations

Horizontal degassers are used in refining operations to remove gas and other contaminants from crude oil. When crude oil is refined, it is heated to high temperatures, which causes it to release gas. This gas must be removed before the oil can be further refined. A horizontal degasser can remove the gas from the crude oil, making it suitable for further refining.

Petrochemical Industry

Horizontal degassers are also used in the petrochemical industry to remove gas and other contaminants from various chemical processes. These contaminants can be harmful to the equipment used in the chemical processes and can also affect the quality of the final products. A horizontal degasser can remove these contaminants, ensuring that the equipment remains safe and the final products are of high quality.

NEXT STEPS...

From arctic conditions, desserts, remote locations to harsh offshore facilities and aggressive desert environments, Kapwell provides world-class products and services. For more information contact our sales representative.